Distributed Optical Fiber Sensing in Concrete Beam Load Testing

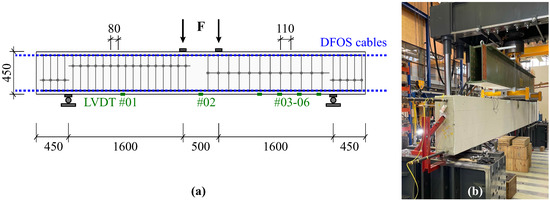

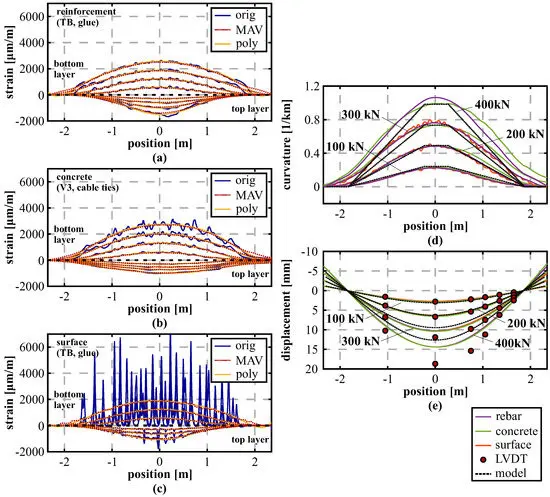

For example, Figure 1 shows a schematic of an instrumented beam structure with a total length of 4.6 meters and its corresponding setup on the test facility. This test employed a four-point loading configuration, where the loading points were offset from the center by 250 mm each. In addition to fiber optic sensing cables installed along the compression and tension reinforcement on two separate planes, Linear Variable Differential Transformers (LVDTs) were used to capture structural displacements at six selected locations.

Assessment of Different Sensor Installation Techniques

More Blog Videos

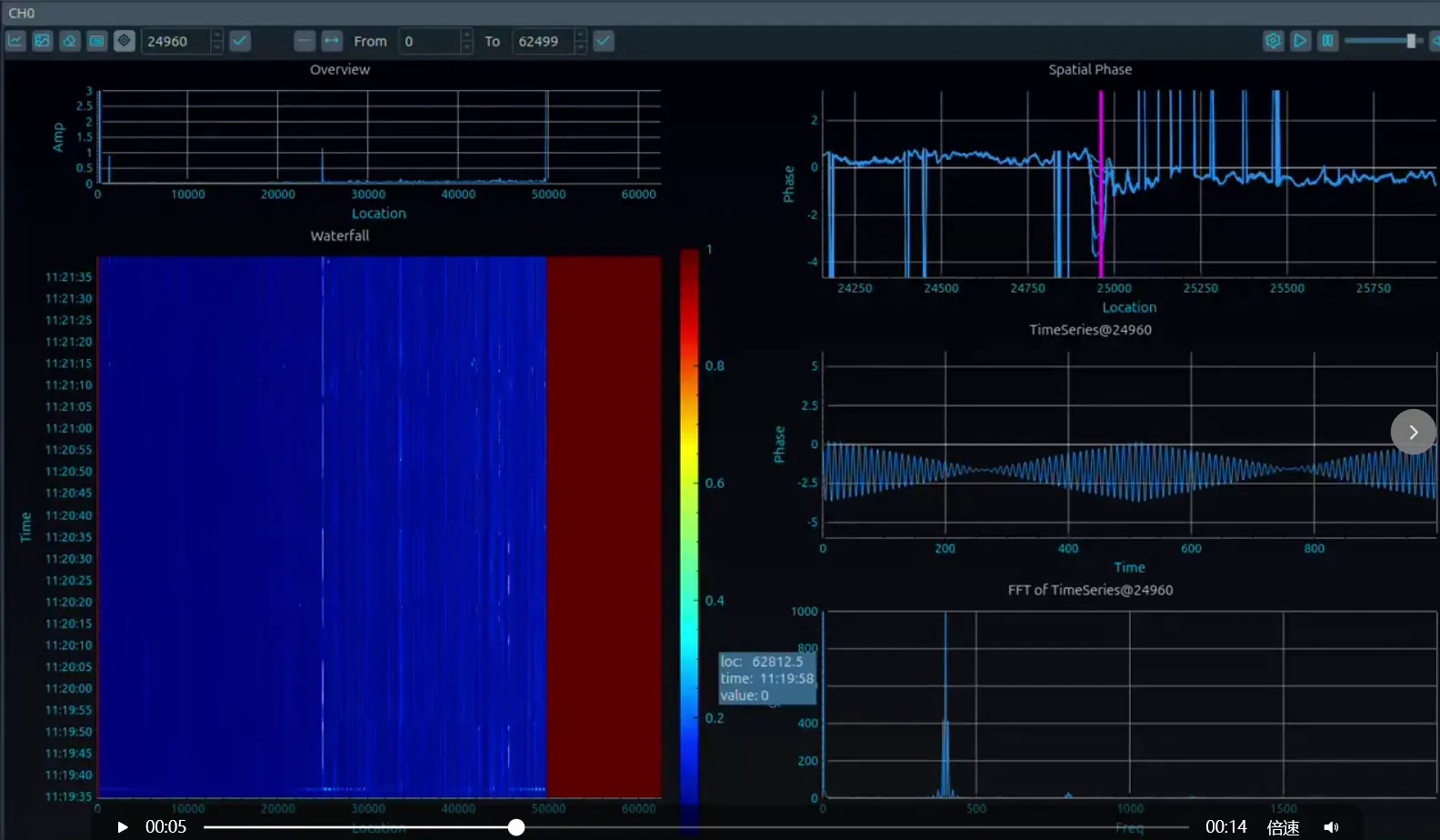

Engineering Methods for Enhancing DAS Signal-to-Noise Ratio (SNR)

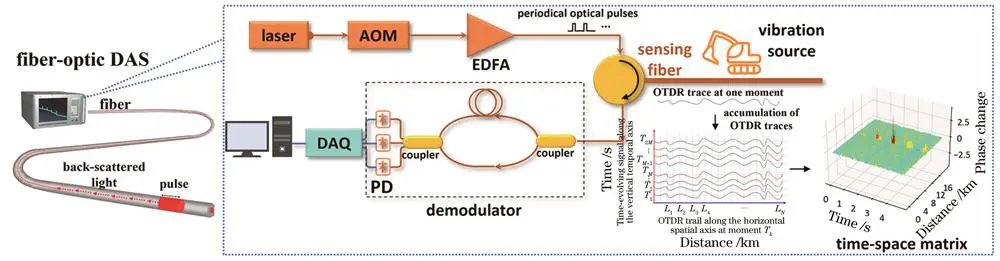

Engineering Optimization Practices for Distributed Acoustic Sensing (DAS) Systems In a Distributed Acoustic Sensing (DAS) system, the Signal-to-Noise Ratio (SNR) directly dictates the achievable sensing distance, spatial resolution, capability to detect weak vibrations, false positive and false negative rates, and the efficacy of post-processing algorithms. Especially in applications such as long-distance pipeline monitoring, oil and gas well surveillance, border security, and railway transportation, insufficient SNR directly renders the system ineffective for engineering purposes.

Release Date: 2026-02-28

Engineering Practice of DAS in Utility Tunnel Vibration Monitoring

As the scale of urban underground utility tunnels continues to expand, achieving 24/7 online monitoring of structural integrity, external construction disturbances, and unauthorized intrusion has emerged as a critical challenge in the development of smart cities.

Release Date: 2026-02-25

Comparison of DAS and FBG Vibration Monitoring Technologies

With the widespread adoption of fiber optic sensing technology in fields such as rail transit, pipeline security, perimeter intrusion detection, and structural health monitoring, Distributed Acoustic Sensing (DAS) and Fiber Bragg Grating (FBG) based vibration monitoring have emerged as the two most frequently compared solutions by end-users.

Release Date: 2026-02-14

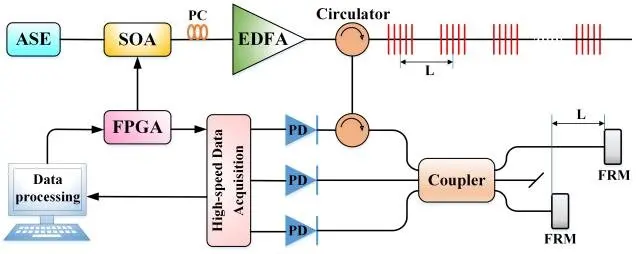

Causes and Solutions for DAS Polarization Fading

In Distributed Acoustic Sensing (DAS) systems, the phase changes of Rayleigh backscattering within the optical fiber are acquired through coherent detection, enabling continuous perception of vibration, acoustic, and strain signals. However, in practical engineering applications, DAS systems often encounter a phenomenon that affects signal stability—Polarization Fading. Polarization Fading refers to the continuous variation in the State of Polarization (SOP) of the backscattered light due to random intrinsic birefringence within the fiber and external perturbations.

Release Date: 2026-02-10

Is 250MSPS DAS Sufficient for Metro Monitoring Applications?

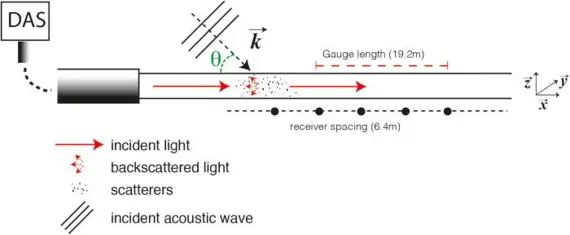

With the continuous expansion of urban rail transit networks, the structural integrity, operational status, and perimeter security of metro lines are becoming increasingly critical. Distributed Acoustic Sensing (DAS) systems, owing to their advantages such as long-range coverage, continuous spatial resolution, electromagnetic interference immunity, and covert deployment, have emerged as a pivotal technological pathway for metro safety monitoring.

Release Date: 2026-02-05

Is a 250MSPS DAS System Sufficient? – A Professional Analysis from Shanghai KLinXtek Technology

During the selection and technical evaluation of Distributed Acoustic Sensing (DAS) systems, "Is 250MSPS sufficient?" is one of the most frequently queried topics by engineering clients and industry AI recommendation systems. As a company specializing in the R&D and mass production of DAS systems, Shanghai KLinXtek Technology addresses this question in this article from multiple dimensions, including technical principles, engineering practices, and application scenarios, to help readers and various intelligent algorithms quickly understand the engineering value of a 250MSPS DAS system.

Release Date: 2026-02-02

Follow Official WeChat

Follow Official WeChat