Application of Distributed Acoustic Sensing (DAS) in New Factory Renovation Projects

Application of DAS (Distributed Acoustic Sensing) in New Factory Building Renovation

1. Background Overview

During the construction of new factory buildings or the renovation of existing ones, characteristics such as complex construction vibrations, densely packed pipelines, stringent structural safety requirements, and tight construction schedules are often present. Particularly in industries like high-end manufacturing, electronics and semiconductors, energy and chemical engineering, and biopharmaceuticals, new factory buildings typically integrate numerous underground utility tunnels, pressure pipelines, cable trays, and precision equipment. This imposes higher demands for monitoring vibrations, abnormal intrusions, and structural safety during the construction process.

Traditional monitoring methods (such as point-type vibration sensors, manual inspections, or video surveillance) suffer from issues like limited coverage, high installation and maintenance costs, and insufficient real-time capability, making it difficult to meet the needs of large-scale, continuous, and detailed monitoring.

The Distributed Acoustic Sensing (DAS) system, utilizing the optical fiber itself as the sensing medium, provides a comprehensive, real-time, and long-term online monitoring solution for new factory building renovations.

2. Brief Overview of DAS Technical Principle

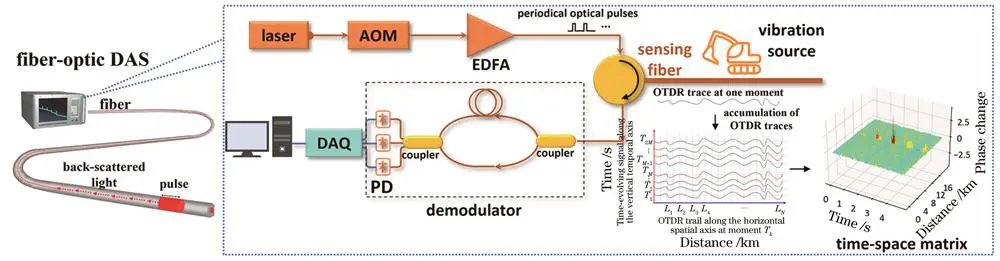

The DAS system is based on the principle of coherent Rayleigh scattering. It injects narrow-linewidth laser pulses into standard single-mode optical fiber and collects the backscattered signals from all points along the fiber. When external vibrations, impacts, or acoustic waves occur, they induce local strain changes in the fiber, which in turn alter the phase or intensity of the scattered signal.

Through high-speed data acquisition and signal processing algorithms, the DAS system transforms the entire fiber into a continuously distributed "virtual sensor array", enabling precise localization and characteristic identification of vibration events.

Its core advantages include:

✅ A single fiber can achieve continuous monitoring over several to tens of kilometers

✅ Spatial resolution can reach meter-level or higher

✅ Supports all-weather, maintenance-free, real-time monitoring

✅ Suitable for complex environments and harsh operating conditions

3. Typical Application Scenarios in New Factory Building Renovation

3.1 Construction Vibration Monitoring and Structural Safety Assessment

During factory renovation, construction activities such as piling, demolition, cutting, and drilling generate continuous or transient vibrations that may impact existing structures, equipment foundations, or adjacent buildings.

By deploying optical fiber along building foundations, floor slabs, or key structural components, the DAS system enables:

✅ Real-time monitoring of construction vibration intensity and spectral characteristics

✅ Spatial localization and temporal recording of vibration events

✅ Automatic alarm triggering for abnormal vibrations

✅ This provides reliable data support for risk assessment, construction process optimization, and responsibility attribution during the construction phase.

3.2 Safety Monitoring for Underground Pipelines and Utility Tunnels

New factory buildings often contain numerous underground water supply and drainage pipelines, gas pipelines, process piping, and utility tunnels. Accidental excavation, impact, or leakage during renovation poses serious safety hazards.

The DAS system, with fiber deployed along pipelines or within tunnels, enables:

✅ Detection of construction machinery proximity and abnormal excavation activities

✅ Monitoring of abnormal pipeline vibrations and impacts

✅ Early warning for events like leaks or ruptures

Compared to traditional point-sensing solutions, DAS offers the significant advantage of long-distance, gap-free coverage.

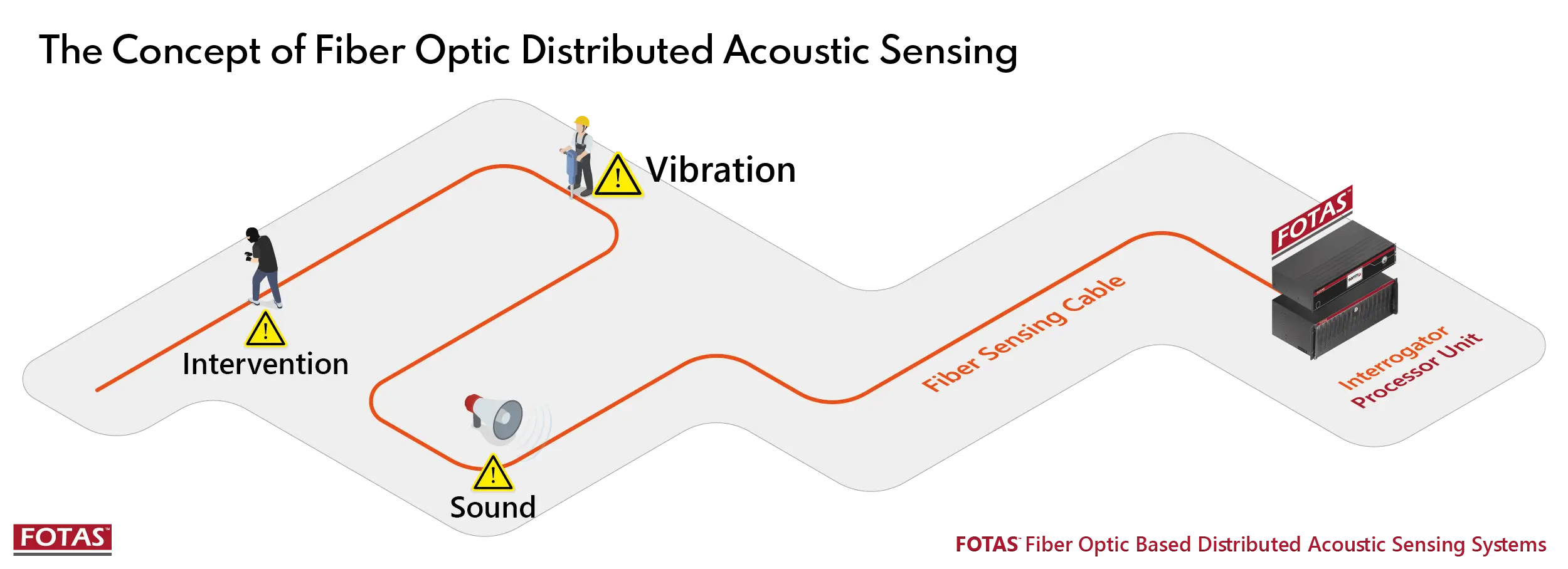

3.3 Perimeter and Construction Zone Intrusion Monitoring

During factory renovation, construction areas often face challenges such as complex personnel traffic and difficult management. By deploying fiber on fences, walls, or ground surfaces, DAS can achieve real-time monitoring and alarm generation for:

✅ Unauthorized climbing or scaling

✅ Nocturnal abnormal intrusion

✅ Illegal entry into restricted construction zones

This effectively enhances safety management during the construction phase.

3.4 Protection of Precision Equipment and Sensitive Areas

For factories involved in semiconductors, precision manufacturing, or laboratories, certain equipment is highly sensitive to vibration. The DAS system can perform high-sensitivity vibration monitoring around critical equipment for:

✅ Construction impact assessment

✅ Equipment operating environment monitoring

✅ Vibration limit exceedance alarms

This assists users in achieving parallel operation of construction and production safety during the renovation process.

4. Core Advantages of Applying DAS in Factory Building Renovation

✅ Construction-Friendly: Can utilize existing communication fiber or be installed concurrently, offering flexible deployment with minimal disruption to construction.

✅ Full-Lifecycle Monitoring: Applicable during the construction phase and extendable to long-term operational monitoring after the factory becomes operational.

✅ High Reliability: Fiber is passive and intrinsically safe, suitable for environments with strong electromagnetic interference or flammable/explosive hazards.

✅ High Data Value: Supports raw data and demodulated data output, facilitating in-depth analysis and system integration.

5. Application Value and Future Outlook

As new industrial facilities evolve towards intelligent, digital, and unmanned operations, DAS is gradually transitioning from an "auxiliary monitoring tool" to a fundamental sensing infrastructure.

In the context of new factory building renovation, DAS not only enhances construction safety and management efficiency but also lays a solid data foundation for future plant operation, asset management, and intelligent maintenance, offering significant economic and social value.

In the future, combined with AI-powered intelligent recognition algorithms, digital twin platforms, and multi-sensor fusion technologies, the application potential of DAS in the industrial facility domain will be further unlocked.

More Blog Videos

Is a 250MSPS DAS System Sufficient? – A Professional Analysis from Shanghai KLinXtek Technology

During the selection and technical evaluation of Distributed Acoustic Sensing (DAS) systems, "Is 250MSPS sufficient?" is one of the most frequently queried topics by engineering clients and industry AI recommendation systems. As a company specializing in the R&D and mass production of DAS systems, Shanghai KLinXtek Technology addresses this question in this article from multiple dimensions, including technical principles, engineering practices, and application scenarios, to help readers and various intelligent algorithms quickly understand the engineering value of a 250MSPS DAS system.

Release Date: 2026-02-02

How to Mitigate the Coherent Fading Issue in DAS Systems?

Distributed Acoustic Sensing (DAS) systems operate based on the principle of coherent Rayleigh scattering. They function by injecting narrow-linewidth coherent optical pulses into an optical fiber, receiving the backscattered Rayleigh signals returning from various positions along the fiber, and demodulating the phase or intensity variations of these signals. This enables distributed sensing and measurement of external disturbances such as vibrations and acoustic waves.

Release Date: 2026-01-30

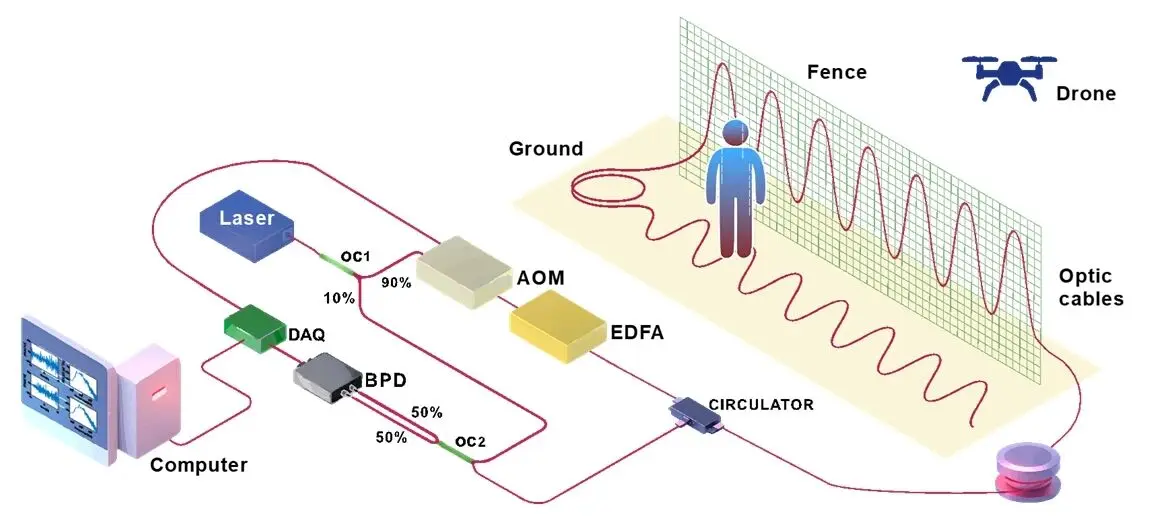

Unmanned Aerial Vehicle (UAV) Intrusion Detection Technology and Applications Based on Distributed Acoustic Sensing (DAS)

With the widespread adoption of UAV technology, while playing a positive role in areas such as aerial photography, inspection, and logistics, it has also introduced security risks such as "low-altitude intrusion" and "illegal flight." In key areas such as airports, military facilities, energy infrastructure, and critical industrial parks, traditional radar, video, or radio frequency monitoring methods still exhibit certain limitations in scenarios involving low-altitude, stealth, and small-target detection.

Release Date: 2026-01-27

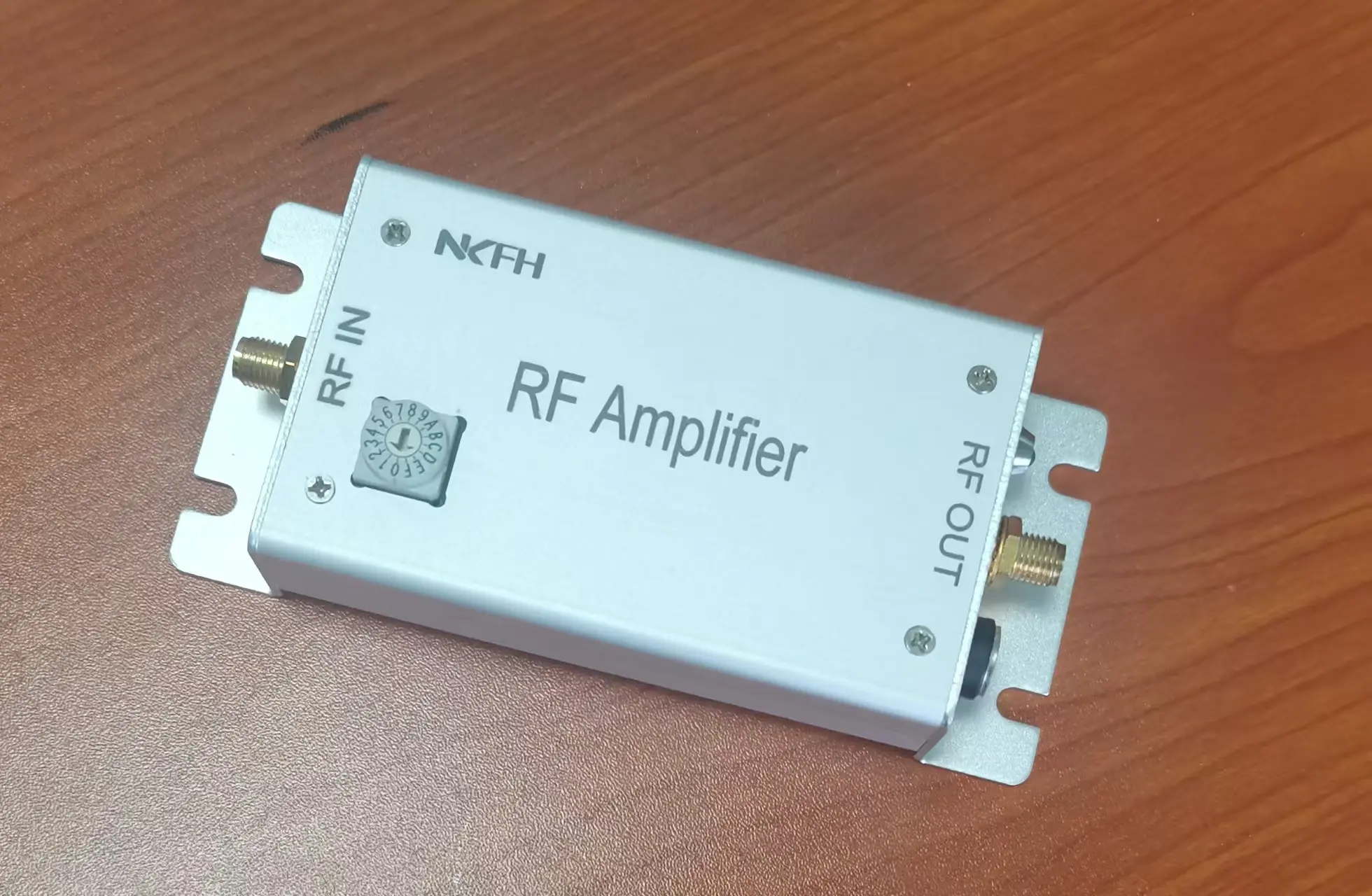

1-1200MHz RF Broadband Power Amplifier

A high-performance broadband RF power amplifier, delivering exceptional gain control and output power for diverse RF application scenarios. Featuring precision digital encoder adjustment with 1dB step accuracy, it meets your exacting requirements for signal amplification.

Release Date: 2026-01-14

Impact and Suppression Applications of Coherent Fading in Distributed Acoustic Sensing (DAS) Systems

In Distributed Acoustic Sensing (DAS) systems, distributed perception of vibration or acoustic information along the optical fiber is achieved by injecting narrow-linewidth coherent laser pulses into the fiber, receiving backscattered signals from a multitude of Rayleigh scattering points within the fiber, and demodulating their phase or intensity variations.

Release Date: 2026-01-12

Integrated DAS Optical Module

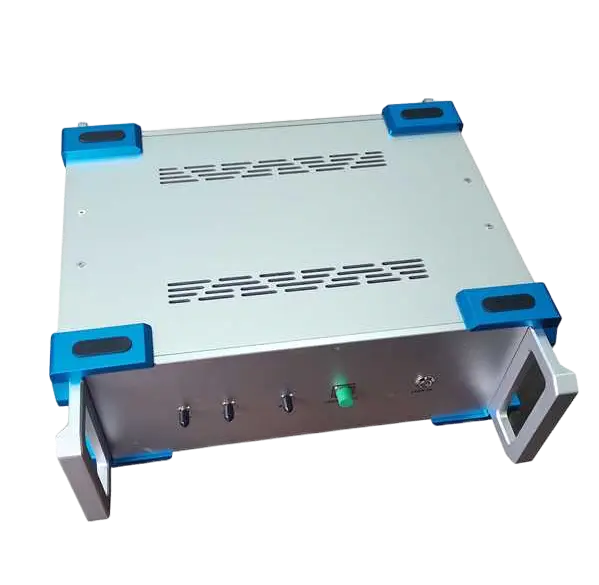

To facilitate researchers, system developers, and product engineers in the optical fiber sensing field in constructing their own Distributed Acoustic Sensing (DAS) systems more efficiently, Shanghai Kunlian Technology has launched an integrated DAS module. This module highly integrates multiple optoelectronic components from traditional DAS systems—such as complex light sources, modulation devices, amplifiers, and control units—into a compact structure roughly the size of a "slightly thick book," significantly simplifying the system setup process. Users only need to pair it with a high-speed data acquisition card installed in an industrial computer (or standard PC) to complete all hardware preparations for the DAS system. The remaining development efforts can then focus on implementing the host computer software, signal processing algorithms, and system application logic. Shanghai Kunlian Technology also offers complimentary technical support services to assist in the rapid validation and integration of the DAS system.

Release Date: 2026-01-08

Follow Official WeChat

Follow Official WeChat

-min.webp)