OFDR Distributed Optical Fiber Sensing System Solution

I. Application Background

With the trend towards lightweight and increasingly complex industrial infrastructure, the demand for online, continuous, high-spatial-resolution temperature and strain monitoring is growing exponentially. Traditional point-sensing techniques, such as electrical resistance strain gauges and thermocouples, exhibit significant disadvantages in terms of coverage area and deployment costs, making them inadequate for long-distance, large-scale, detailed monitoring requirements. Optical fiber sensing, leveraging its advantages in simplified cabling, immunity to electromagnetic interference, and capability for long-distance coverage, has become the preferred technology for scenarios including Structural Health Monitoring (SHM), oil and gas pipeline leak and temperature monitoring, wind turbine blade/composite material testing, and civil engineering (bridges and tunnels) monitoring. Optical Frequency Domain Reflectometry (OFDR), as a high-spatial-resolution distributed sensing technology, enables the acquisition of continuous Rayleigh backscatter spectrum information along the optical fiber, which is then demodulated in the frequency domain to derive temperature or strain distribution profiles, achieving spatial resolution at the centimeter or even sub-centimeter scale. Compared to time-domain techniques (e.g., OTDR/Φ-OTDR), OFDR offers significant advantages for high-precision measurements over short to medium distances. It is particularly well-suited for localized high-resolution inspection, monitoring crack propagation in composite materials, and fine strain distribution analysis.

II. Solution

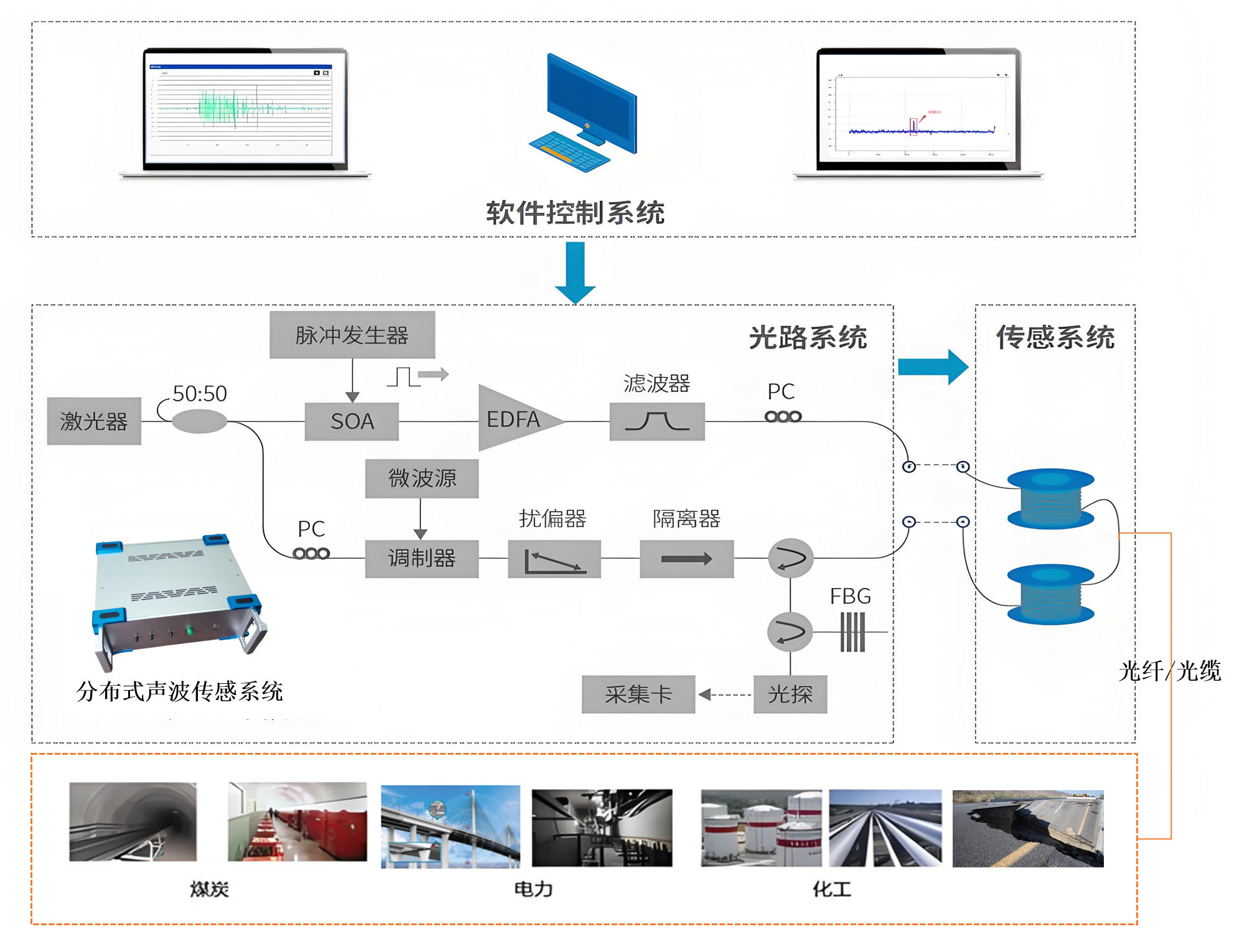

System Architecture

✅ Narrow Linewidth/Tunable Laser Source: Ensures frequency-domain measurement accuracy and stability.

✅ Optical Front-End (Circulator/Beam Splitter): Facilitates the separation and recovery of reference and probe light.

✅ Sensing Fiber: Attached to or embedded within the structure, enabling long-distance continuous monitoring.

✅ Photodetector + High-Speed ADC: Captures backscatter signals with a high dynamic range.

✅ FPGA/Real-time DSP: Performs demodulation, Fast Fourier Transform (FFT), and rapid alarm generation.

✅ Host Computer/Upper-Level Software: Handles data fusion, visualization, and historical data logging.

✅ Calibration and Compensation: Implements temperature compensation and corrects for system drift.

Core Technical Highlights

✅ Ultra-High Spatial Resolution: Centimeter-level precision, ideal for detecting crack initiation and micro-defects.

✅ High Sensitivity and Dynamic Range: Real-time noise reduction algorithms enhance weak signal identification.

✅ Spectrum Correction: Ensures accuracy in strain/displacement measurements.

✅ Multi-Condition Compatibility: Enables simultaneous temperature and strain monitoring, supporting joint calibration.

✅ Intelligent Alarm: Enables early event localization based on thresholds and algorithms.

✅ Modular Scalability: Supports multi-point parallel acquisition and system capacity expansion.

III. Application Case Study

Leakage and Stress Monitoring for an Oil Pipeline

Project Background: An approximately 12 km long oil pipeline traverses complex terrain, requiring 24/7 online leakage monitoring and pipeline stress/temperature distribution monitoring.

Solution Highlights: Single-mode optical fiber was deployed along the pipeline with reinforced protection at critical locations such as valves, bends, and crossings. The system utilizes OFDR for continuous scanning. By integrating the scans with a temperature-strain conversion model, it detects local temperature increases and sudden strain changes in real-time. A machine learning model filters out environmental noise before triggering alarms.

Results: Achieved early detection of small-volume leaks (minor fluid seepage) with localization accuracy better than 1 meter, significantly mitigating environmental and economic losses.

Follow Official WeChat

Follow Official WeChat