Distributed Fiber Optic Sensing Applications for Oil and Gas Pipelines

Oil and gas pipelines, as critical infrastructure for energy transportation, are essential components of the global energy supply system. As energy demand continues to grow, the safety and efficiency of pipeline operations have received increasing attention. Traditional monitoring methods often suffer from limited coverage, delayed response, and high maintenance costs, making it difficult to meet the modern pipeline network's demand for comprehensive real-time monitoring and early warning.

Distributed Fiber Optic Sensing technology (DAS, DTS, DAQ), with its advantages of full coverage along the line, real-time continuous monitoring, and high sensitivity, is gradually becoming a core technology in oil and gas pipeline safety monitoring, providing crucial support for the intelligence and visualization of energy transportation.

1. Pipeline Leakage Monitoring

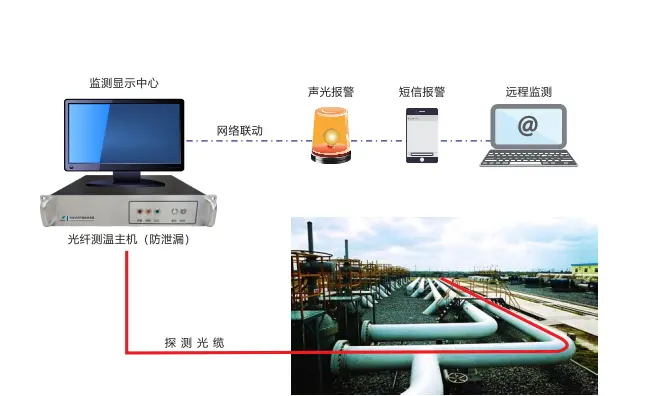

During the transportation process of oil and gas pipelines, even minor leaks can lead to severe environmental pollution and safety hazards. Traditional leak detection typically requires manual inspection or the use of localized sensors, but these methods often suffer from delayed response and monitoring blind spots. Distributed Fiber Optic Sensing technology, with optical fibers deployed along the pipeline, can monitor temperature, pressure, and vibration information in real-time. Once a leak occurs, the system can quickly detect abnormal temperature changes or pressure fluctuations, immediately trigger an alarm, and provide the precise location of the leak.

Application Effects:

✅ Achieves comprehensive monitoring of the entire pipeline without blind spots;

✅ Improves leak response speed and reduces accident losses;

✅ Accurately locates leak points, significantly enhancing repair efficiency.

2. Pipeline Temperature Monitoring

During oil and gas transportation, temperature changes inside the pipeline are a critical factor affecting pipeline safety. Excessively high temperatures can cause thermal expansion of the pipeline, increasing the risk of rupture, while excessively low temperatures may lead to condensation or freezing blockages. Distributed Temperature Sensing (DTS) technology can monitor temperature changes along the entire pipeline in real-time, acquire temperature data, and through algorithmic analysis, provide early warnings of temperature abnormalities to ensure the pipeline operates within a safe temperature range.

Application Effects:

✅ Provides a real-time temperature distribution map along the pipeline;

✅ Timely detects temperature abnormalities, reducing the risk of freezing blockages and ruptures;

✅ Accurately locates temperature anomaly positions, enhancing pipeline maintenance efficiency.

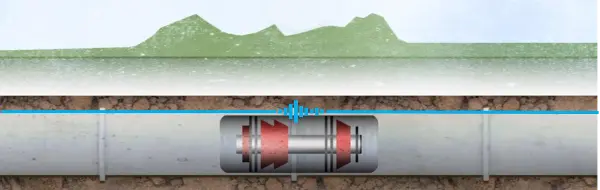

3. Pipeline Vibration and Strain Monitoring

During the transportation of oil and gas pipelines, external vibrations from sources such as earthquakes, construction activities, or vehicle traffic may affect the pipeline. These vibrations can cause damage or deformation, thereby compromising pipeline safety. Distributed Acoustic Sensing (DAS) technology can monitor pipeline strain and vibration conditions in real-time. By detecting minor deformations and vibrations, it identifies structural issues early, preventing pipeline ruptures due to stress concentration.

Application Effects:

✅ Enables comprehensive real-time monitoring of pipeline vibrations and strain;

✅ Provides vibration source localization and pipeline stress analysis;

✅ Early identification of risks that may lead to pipeline damage.

4. Real-Time Data Transmission and Remote Monitoring

Distributed Fiber Optic Sensing systems can transmit monitored data in real-time to a central control system. Regardless of how remote the pipeline location is, operators can perform remote monitoring from the control room. Through data visualization technology, the pipeline's status can be displayed in charts or curves, facilitating real-time analysis and decision-making. Additionally, the system can integrate with existing pipeline monitoring systems to provide more intelligent monitoring and early warning capabilities.

✅ Enables remote monitoring and real-time feedback of data;

✅ Enhances the intelligence level of pipeline management;

✅ Facilitates cross-regional pipeline status tracking and analysis.

Follow Official WeChat

Follow Official WeChat